Unveiling Excellence in Compound Die Manufacturing: Bhavesh Enterprises

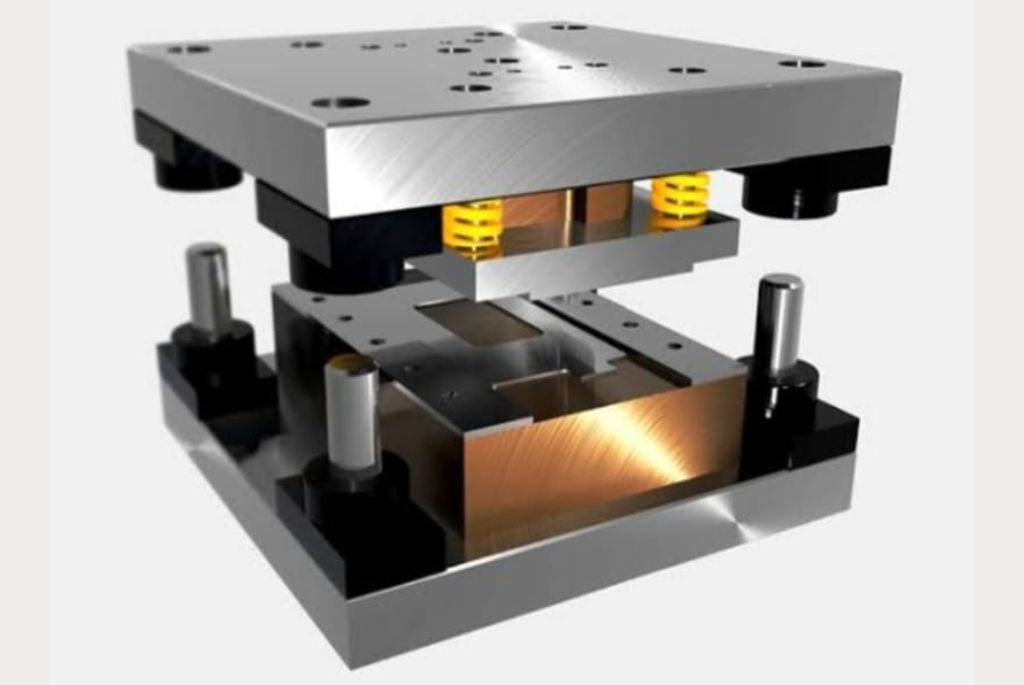

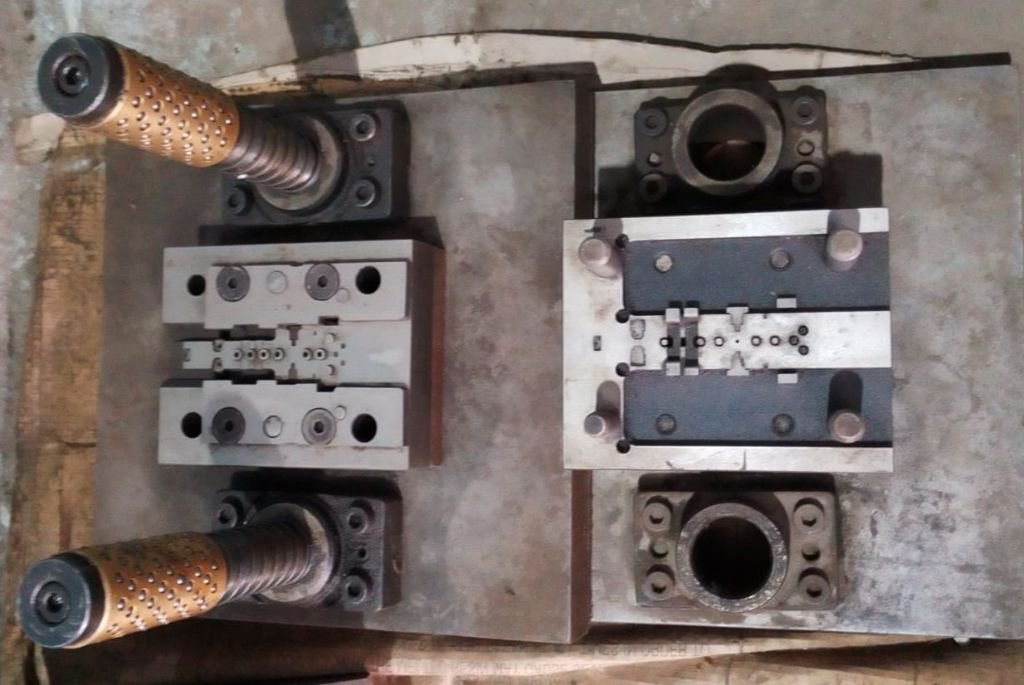

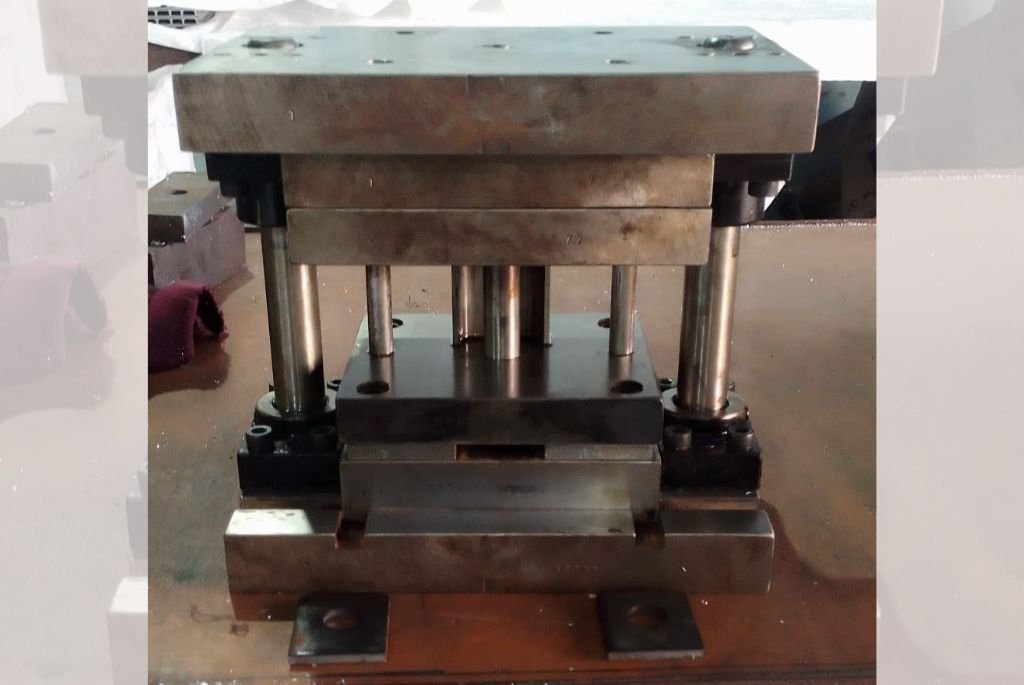

Bhavesh Enterprises is one of the best manufacturers in Bhiwadi NCR and across India for compound dies. We are proud to state this. Our focus on quality, innovation, and customer satisfaction has helped us to become leaders within the compound die manufacturing industry. What is a Compound Die? If you’re making things out of sheet metal, a compound die is a very specialised tool of equipment that can do multiple tasks at once, like cutting, blanking, and forming. Compound Die in Sheet Metal its is a very specific piece of tool for making things out of sheet metal. It can do several things at once, such as cutting, blanking, and forming. This tool makes a huge output scale more productive, cuts costs, and makes things more accurate. Difference Between Compound Die and Progressive Die One of the most common queries we encounter is the difference between compound die and progressive die. Let’s clarify: Compound Die: it forms multiple operations in a single press stroke, making it ideal for high-precision, high-speed production of relatively simple parts. Progressive Die: performs sequential operations across multiple stations, with the sheet metal advancing through each station. This makes progressive die and compound die tools suited for different manufacturing needs. Why Choose Bhavesh Enterprises? When it comes to compound die creation, Bhavesh Enterprises has been in business for decades. Our design team uses advanced CAD/CAM and simulation tools to make dies that are strong, work well, and have little downtime. This makes the company more productive. We work with our clients to understand their exact needs and make sure that our complex die designs go above and beyond what they expect. Progressive and Compound Die: The Best of Both Worlds We understand the advantages of specific uses of progressive die and compound die systems. That is why we offer consulting and design services to help you select the best tool for your use case. From the speed and complexity a progressive die provides to the simplicity and effectiveness of a compound die, we have it all. Serving All Over India with Precision and Passion We, a company based in Bhiwadi NCR, stand out in the compound die industry for having served clients all over India. Our superior infrastructure, skilled employees, and focus on self-development are key differentiators from our competitors. Get in Touch Today If you need help with compound die manufacturing for the fabrication of sheet metals, reach out to Bhavesh Enterprises. Call us today to learn how we can help transform your production processes.