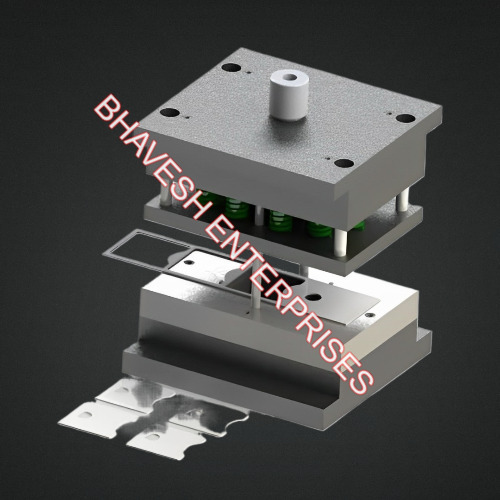

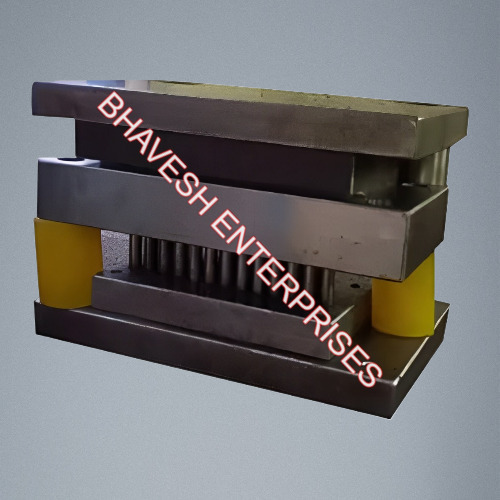

Best Power Press Job Work are used in power press jobs to form, cut, and shape metal and other materials into the required forms and components. Power presses are adaptable tools used in a variety of manufacturing operations, such as bending, stamping, punching, and forming. The following is an in-depth analysis of the duties and content of power press job work:

UNDERSTANDING THE REQUIREMENTS

Job Specifications: Examine and comprehend the dimensions, material type, and quantity, as well as the requirements, of the part that needs to be manufactured.

Blueprints and Drawings: To understand the design and necessary procedures, analyze technical drawings, CAD models, and blueprints.

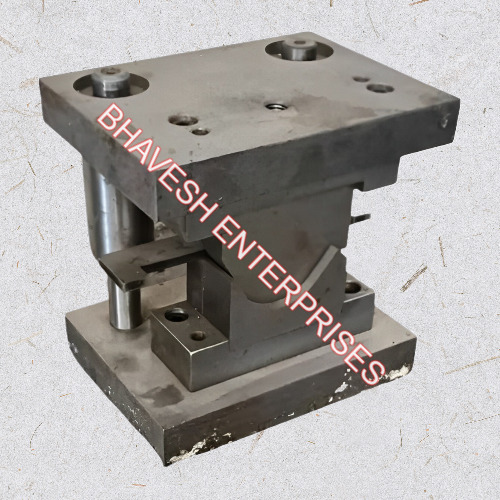

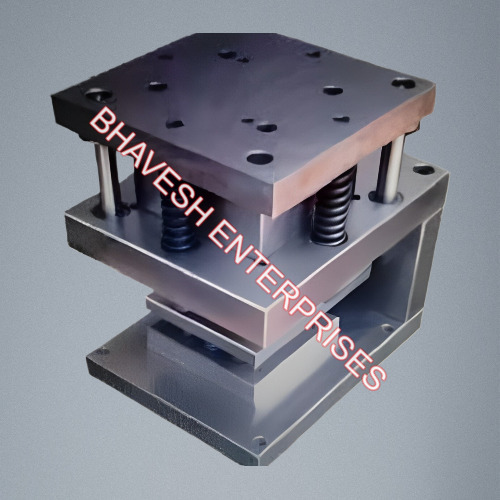

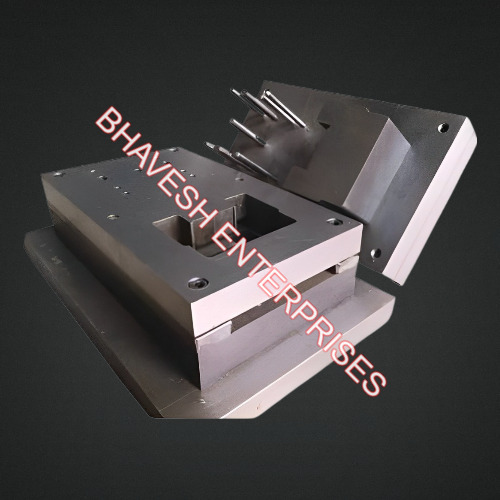

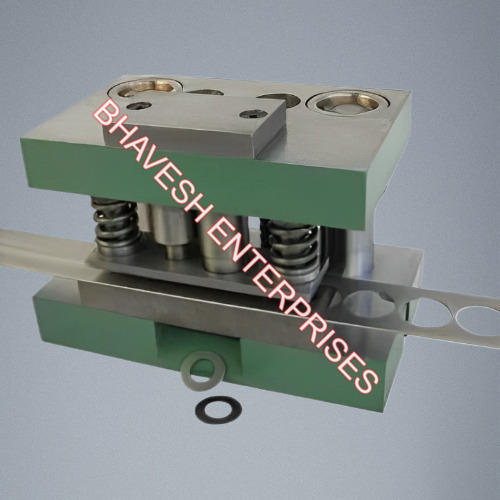

TOOL AND DIE SETUP

Die Selection: Choose the right die for the job at hand (such as cutting, punching, or bending). Die Installation: Put the die in the power press, making sure it's aligned and firmly fixed. Tool Alignment: Align the tools and dies accurately to ensure precision in the operations.

SAFETY AND COMPLIANCE

Safety Procedures: To avoid mishaps and injuries, follow all safety procedures. Using personal protective equipment (PPE) like goggles, gloves, and earplugs is part of this. Regulatory Compliance: Make sure that power press operations and worker safety are in accordance with industry standards and laws.

SKILLS AND TOOLS REQUIRED

Technical Skills: Expertise in power press operation, comprehension of tool and die configuration, and familiarity with metalworking procedures. Precision Instruments: Use of precision measuring instruments for quality control. Problem-Solving: Ability to troubleshoot and resolve issues during the manufacturing process. Attention to Detail: Ensuring high accuracy and quality in all stages of the job work.

Work with Best Power Press Job Work in India bhavesh enterprises is essential for manufacturing sectors that need accurate, productive, and high-grade metal components. Please inquire if you need any help or additional details about any area of power press job work!