Best Sheet Metal Cutting Dies manufacturer in India

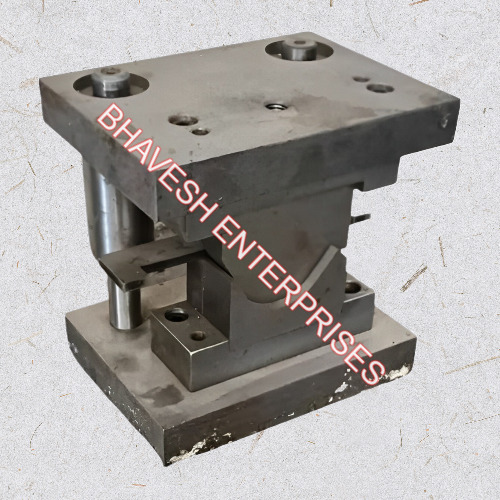

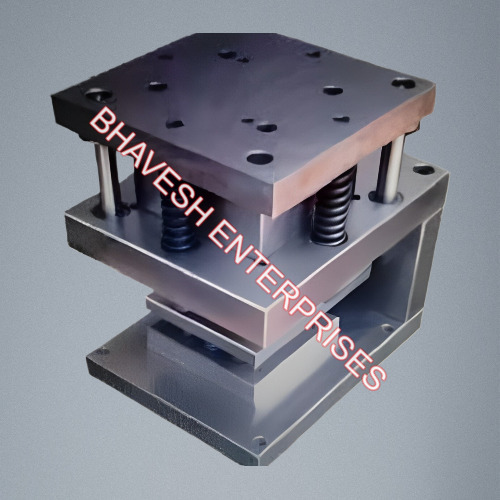

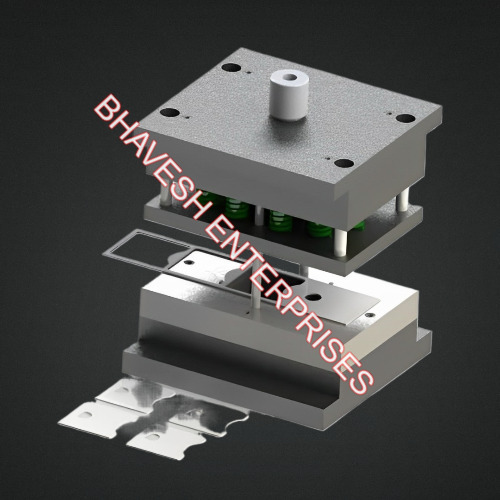

In manufacturing operations, sheet metal cutting dies are instruments that cut and shape metal sheets into predetermined shapes or designs.

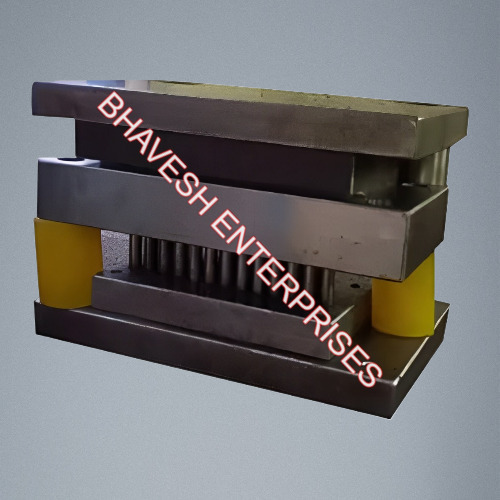

Usually constructed from hardened steel or other robust materials, these dies are intended to endure the intense pressures and strains associated with metal cutting. Best Sheet Metal Cutting Dies manufacturer come in a variety of forms, including:

Sheet metal cutting dies are used to create components for automobile body parts, aircraft panels, home appliances, and electronic enclosures in a variety of industries, including electronics, aerospace, and automotive.

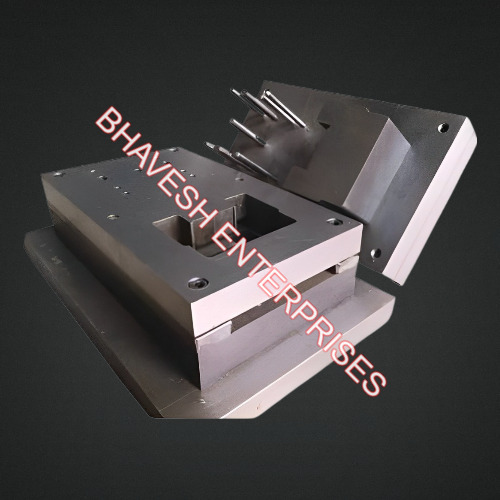

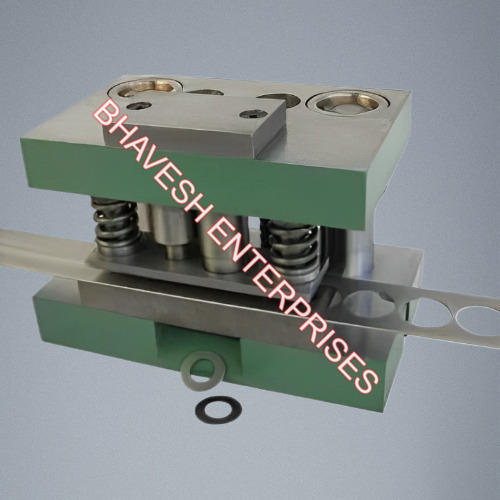

Key Components of Cutting Dies

Die Block: The die's central component, housing the cutting or shaping edges. Punch: The die's component used to force sheet metal through the die block and produce the desired cut or shape. Die Shoe: The base that supports the die block and acts as a surface on which the die can be mounted. Strippers: A tool for taking the punched-out portion out of the punch.

Considerations in Die Design

Material Selection: Materials that are resistant to high pressure and wear must be used to create dies. Clearance: To guarantee clean cuts and little wear, the space between the punch and die must be carefully measured. Maintenance: To keep the die sharp

and in good operating order, regular maintenance is required. Tolerances: To guarantee that the finished product satisfies the necessary requirements, precise tolerances must be maintained.

If you have specific questions or need more detailed information about a particular type of die or its application, feel free to ask!